If you are a car guy, specifically a car guy with a turbocharged vehicle, and you spend any time at all on the internet, you have either asked the question at some point yourself and/or seen someone ask the question many times. There is no better way to light yourself an E-fire than to ask this question in a public forum. However, there are so many opinions running rampant all over the net, that I don’t really blame people for asking this simple question anymore. There is no definitive answer. So the best way to answer this question is to explain a bit better about the different types of valves so that you can make an informed decision.

What is a Blow-off-Valve?

A blow-off-valve by any other name, would it still sound as sweet? Though it is the most popular nomenclature, blow-off-valve (BOV) is one of many names used to describe a pressure release system on a turbocharged vehicle.

Bypass valve, recirc valve, or diverter valve, all of these different names represent this pressure release system of which the primary purpose is to protect the turbocharger.

Why does the turbo need protection? The answer is, because Compressor Stall. Compressor stall happens when the turbo crosses its surge line on a compressor map. The reason it will do this is that it is operating at too high of a pressure ratio for the given airflow. The easiest way to force a turbo over the surge line is to close the throttle body and shut off airflow. The pressurized air has nowhere to go but back out the compressor housing and escape through the intake. This back flow of air can stop or quickly slow the turbo from spinning and is extremely hard on the components of the turbocharger.

Every time you close the throttle on a boosted car there will be some pressure in between the compressor and the throttle body. With a pressure release system in place, that air can escape through a place other than the compressor inlet.

Every time you close the throttle on a boosted car there will be some pressure in between the compressor and the throttle body. With a pressure release system in place, that air can escape through a place other than the compressor inlet.

The blow-off-valve/bypass valve is that pressure release system on a turbocharged car. These are also refered to as diverter valves since they divert air from the presurized charge pipe to a lower pressure area. The difference between a blow-off-valve and a bypass valve is that a blow-off-valve diverts the excess pressure to the atmosphere while a bypass valve diverts it back to the intake pre-turbo.

How do they work?

Any blow-off-valve will utilize either a diaphragm or a piston to function at holding back pressure or releasing it. They can be configured to either push or pull open, and for the tech savy, you can get fancy with the sequential or synchronic valves as well.

|

|

Diaphragm from a Tial Q BOV You can see the piston in this Turbosmart Plumb Back Valve

Push Valves have pressure pushing against the valve which wants to open. A spring is utilized to keep it closed. It actuates when the vacuum resulting from a throttle closure combines with the pressure in the charge pipe to overcome the spring pressure. Push style valves are suited best for lower boost/flow setups. They can actuate very quickly and are desired for situations where the throttle position will be changing rapidly. While the push style valve is less likely to cause compressor surge, it is more likely to leak under higher boost pressures.

Pull Valves require pressure pushing against the valve that naturally wants to close. It actuates when the vacuum that results from a throttle closure combines with the pressure from the charge pipe to overcome the spring pressure and pulls the valve open. Though its reaction time is slower, it works well in higher boost applications, especially where shifting happens fast, such as drag racing. There is a greater chance for compressor surge to occur, but since they don’t drop pressure as quickly as the push style valve, there will still be some pressure remaining in the system when shifting quickly. This can help get you back in the power sooner.

Diaphragms can be found in both push and pull valves. The diaphragm valve utilizes a disc on a shaft that seals against either a machined or o-ringed surface. A diaphragm that is sealed and isolated in another chamber is used to actuate this disc. This style of valve is usually pretty durable, but the diaphragm itself is a point of weakness since it is prone to wear.

Diaphragms can be found in both push and pull valves. The diaphragm valve utilizes a disc on a shaft that seals against either a machined or o-ringed surface. A diaphragm that is sealed and isolated in another chamber is used to actuate this disc. This style of valve is usually pretty durable, but the diaphragm itself is a point of weakness since it is prone to wear.

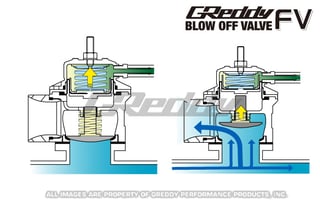

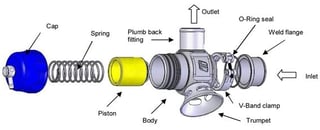

You will usually only find piston style valves in use with the push strategy, though not always. The piston seals with an o-ringed surface and blocks the outlet of the valve as well. A spring is used to keep the valve closed and vacuum pressure is needed to actuate it. Piston style valves require maintenance and lubrication in order to keep functioning normally. Neglecting them can lead to premature failure.

You will usually only find piston style valves in use with the push strategy, though not always. The piston seals with an o-ringed surface and blocks the outlet of the valve as well. A spring is used to keep the valve closed and vacuum pressure is needed to actuate it. Piston style valves require maintenance and lubrication in order to keep functioning normally. Neglecting them can lead to premature failure.

Believe it or not, the valves listed above are just the simpletons. The fancier options come in the form of Synchronic and Sequential Diverter Valves. I’m sure most of you have heard of the HKS Super Sequential Valve (SSQV) or the Synapse Engineering Synchronic Diverter valve. Well the name isn't just fancy marketing, it acutally means something.

|

|

HKS SSQV Blow-off Valve Synapse Super Synchronic Diverter Valve

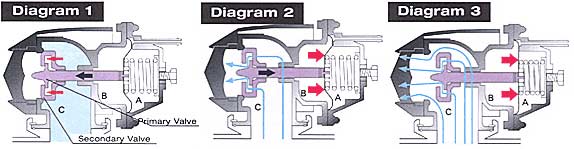

A sequential valve has two valves that operate under different situations. A smaller valve is used to vent air under lower pressure/flow situations while both are used to vent under much higher boost/flow conditions. While it is a pull style valve, it behaves very much like a push style valve and can therefore take on the advantages of both.

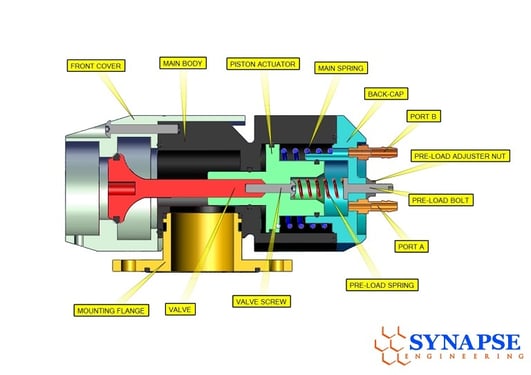

Synchronic valves just do things a little differently. They are a pull style valve, but they use both a boost and vacuum signals to operate the valve. This setup allows the valve to actuate incredibly fast. However, on a car that uses a Mass Airflow Sensor, this type of valve cannot be vented to atmosphere. That being said, it is worth it because this valve is perfectly designed to eliminate compressor surge and work perfectly under all engine conditions.

Recirculating a blow-off-balve vs venting it to atmosphere:

There are several reasons why the OE Manufacturers choose to use fully recirculated bypass valves. One reason is that they are quiet. The OE is always working to quiet down engine noise and this is why you see the accordion intakes and silencer/resonator pipes that cut down on engine noise. Recirculating valves don't make as much noise as fully atmospheric valves. However, if you are running an aftermarket intake that deletes all that silencer stuff, you will certainly be able to hear your recirculating valve plenty fine. Another reason for a recirculated valve would be because the vehichle is mass airflow (MAF) based and they need to keep the metered air in the system in order to prevent throwing off the ECU. Recirculating the BOV can also have positive effect on transient response as air being vented from the charge pipe is being pushed right back towards the turbo which helps to fill any vacuum restriction between the air filter and turbo between shifts. This would allow you to get back into boost quicker and reduce lag between gear changes.

Atmospheric blow-off-balves are much louder than their recirculated counter parts. They are more necessary on high boost/flow vehicles that need to vent a lot of air. The atmospheric valves are more popular because of the sounds they make. However, certain vehicles do not run well in this configuration.

What is right for you?

If you are thinking of upgrading your factory diverter valve, you should first consider what configuration your vehicles is. If it is Speed Density, like the Ecoboost Mustang, the Focus ST, or the Focus RS, or even a converted WRX or STI, then a fully atmospheric blow-off-valve will work just fine. However, if your car is MAF based like the Mazdaspeed 3 and 6, or the WRX/STI as it comes from the factory, an atmospheric blow-off-valve will make for a rougher ride.

So when choosing a blow-off-valve or bypass valve, you should first decide if you are more of a form over function or function over form kind of person. Vent to atmosphere (VTA) valves are much louder and for some that is a huge plus, but on modern cars, they don't always function as well as the recirc valves. However, on most cars, with an intake, you can still hear the recirc valve plainly. There are also hybrid valves that can fill the void for those who want the best of both worlds.

So when choosing a blow-off-valve or bypass valve, you should first decide if you are more of a form over function or function over form kind of person. Vent to atmosphere (VTA) valves are much louder and for some that is a huge plus, but on modern cars, they don't always function as well as the recirc valves. However, on most cars, with an intake, you can still hear the recirc valve plainly. There are also hybrid valves that can fill the void for those who want the best of both worlds.

Next, you must plan ahead. If you will be running a larger turbo and will need to vent a lot of air, go ahead and get a valve that can support that. Otherwise, they aren't really necessary and unless you are just in it for the sound, a smaller stock replacement valve will be more functional for you.

Finally, do you really need to upgrade from your factory valve? Well, if you are staying stock and not planning on tuning, the answer is no. But if more boost is in your future, you may want to consider a valve that will be able to hold that boost without leaking and causing you any pesky power loss.

Topics: