Believe it or not, you can have a turbo that is too big… Well, perhaps too big is the wrong way to word it. You can have a big turbo that is not matched properly with your engine or even matched properly with itself (size of hotside vs compressor). While this isn’t really an issue for big v8’s or even v6’s really, the problems from this phenomena will be most evident on small displacement turbo 4 cylinders.

First thing I want to say is, I am a huge advocate for bigger turbos, but there is a right way to do it and a wrong way to do it. While I don’t consider myself to be a turbo expert from an engineering standpoint, I did learn a few things recently from a firsthand experience with a mismatched turbo and will be sharing those things with you now.

Let’s set the stage:

The car is a 2006 Mazdaspeed 6 with a built motor running meth injection. The turbo is a massive hybrid, and the specs are somewhat of a mystery. It started life as a GT3582, but got rebuilt with some custom components to make it flow more air (a lot more air). Now, while this turbo would be perfectly acceptable on a larger displacement, or better flowing engine, it proved to not be so perfect on this particular Speed 6.

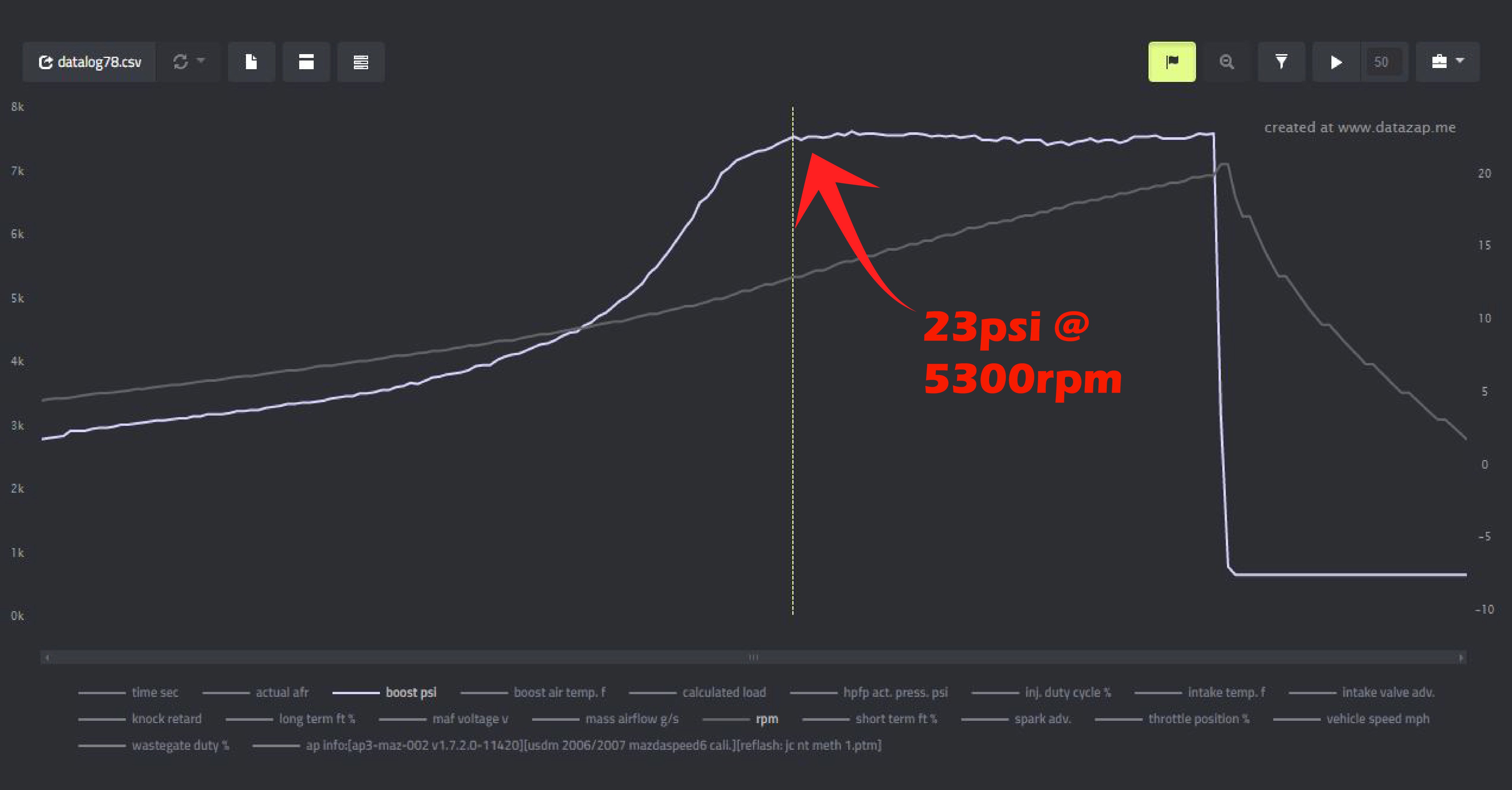

Spool was very slow making for a very narrow power band. The car was pretty much useless below 5000rpm. It was hitting peak torque around 5500rpm, and at 23psi, was nowhere close to its efficiency range. This is a high altitude car as well, so all the issues get even more pronounced.

What happens if we turn up the boost?

Well first of all, we need to turn on the meth because it is out of fuel already. Once meth is on and afr’s look good, we give it more wastegate duty cycle (WGDC) and start walking the boost up. It starts making more power, but the logs are looking kind of odd.

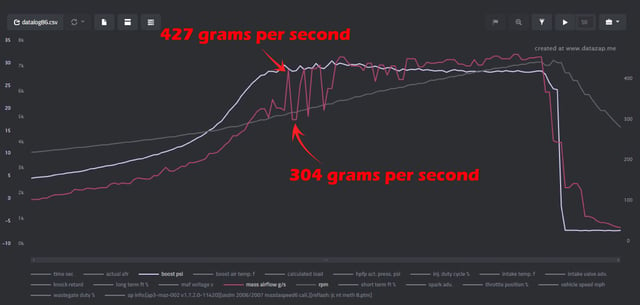

It starts to become noticeable at around 26psi and then gets worse from there. Massive boost spikes make it look like the turbo is running into a wall and getting accordioned like a cartoon. The airflow responds this way too. It is in grams per second (g/s), and is measured by the Mass Airflow Sensor (MAF sensor). It tells a very interesting tale as well. You can see 120+ g/s spikes in the MAF readout. Something is clearly wrong!

A little more investigation:

While it is clear something is very wrong, the customer reports no noticeable stuttering or anything and says it runs smoothly. He does say he can hear some bov chatter at spool up though. While I can’t understand how 120 g/s swing isn’t noticeable, the chatter sound clearly points to compressor surge.

I remember the first time I heard compressor surge in person. Many years ago at the first Epic East Coast Nator Meet thrown by the Mazdapseed community, we had a dyno day and one of the speed 6’s that dyno’ed was sporting a twin scroll GT3076. The twin scroll allowed it to spool faster and push more air volume at lower rpms. On every pass, the car would buck a little and chatter as the compressor over ran what the engine could actually take in at the lower rpms. It sounded like the blow off valve releasing but it was occuring during boost and you could see the air filter convulse as air was trying to come out and go back in.

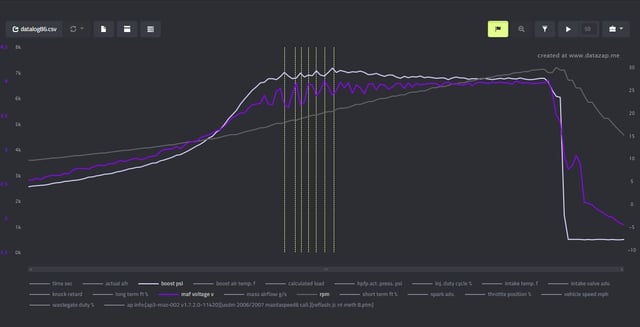

So when he said it sounded like BOV chatter, I decided to take a closer look at the logs and draw on the knowledge of an old friend. Dustin with PERM tuning had me compare the MAF Voltage with the boost spikes.

As you can see, they are inversely proportional. When the boost spikes up, the MAF spikes down, and when the boost drops, the MAF spikes up. This tells us that the turbo is back flowing into the intake through the surge ports on the turbo. The pressure builds up but isn’t ingested by the engine, instead, it goes back out the intake. When the pressure releases out the intake the MAF sensor reads it a second time showing up as a spike in voltage.

The surge ports, or Anti-Surge, on the compressor housing is there to protect the turbo in the event of compressor surge. Compressor surge is incredibly hard on a turbo as the backflow of pressure has the ability to quickly and completely stop the compressor wheel from spinning. Anti-Surge gives the back flowing pressure an escape route around the compressor wheel and helps to minimize the damage it can cause.

The surge ports, or Anti-Surge, on the compressor housing is there to protect the turbo in the event of compressor surge. Compressor surge is incredibly hard on a turbo as the backflow of pressure has the ability to quickly and completely stop the compressor wheel from spinning. Anti-Surge gives the back flowing pressure an escape route around the compressor wheel and helps to minimize the damage it can cause.

You can see the surge porting on the compressor cover to the left. The four ovalish cutouts just to the inside of the compressor inlet. With out these, this turbo would have torn itself apart.

After playing around with some different boost levels, I found that I could keep it from surging below 26psi, but this made for an even more lethargic setup and the customer decided to get a different turbo instead.

What this tells us:

This tells us that clearly, the turbo was not a proper match for this engine. It pushed far more air than what the engine could take in, even at the higher rpm’s it was spooling at. If the turbo spooled a little slower, it would probably be fine, but peak torque at 5500rpm is already a bit too slow and even reving out to 7500rpm isn’t going to pick up enough range to justify the slower spool.

So the best bet when picking a big turbo for your car is to pick a turbo that will make good use of the power band, and not overflow the engine. Most people will not have a problem with this as most people’s power goals are not as high as this particular customers’. However, more power can be made on smaller setups when they are run efficiently and when everything is sized properly.

Topics: